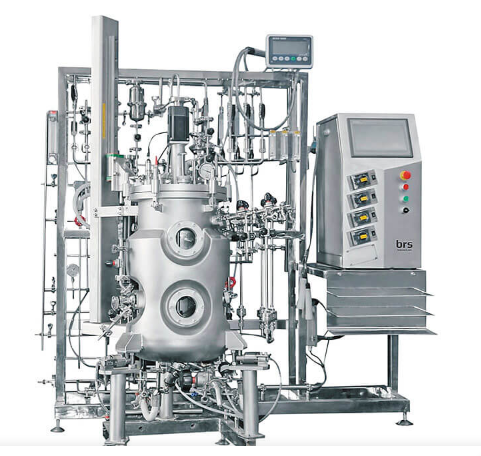

Playing a critical role in the development and manufacturing of a range of medical products, including antibiotics, vaccines, and biopharmaceuticals our company production equipment for this procecess. Utilizing bioreactors is essential in this process, as they provide the controlled environments necessary for optimal microbial growth and product synthesis.

Microorganisms, such as bacteria, yeast, and fungi, are key players in pharmaceutical manufacturing. For instance, the well-known bacterium Streptomyces is employed to produce various antibiotics, such as streptomycin and tetracycline. Yeasts, particularly Saccharomyces cerevisiae, are used in the production of recombinant proteins, while fungi like Penicillium chrysogenum are essential for penicillin production.

Bioreactors are specifically designed to maintain ideal growing conditions for these microorganisms. Critical parameters, including temperature, pH, oxygen levels, and nutrient supply, are meticulously controlled to ensure maximum yield and productivity. For example, aerobic bacteria require sufficient oxygen supply, which can be facilitated through specific agitation and aeration techniques implemented in the bioreactor.

One of the significant advantages of using bioreactors in pharmaceutical production is their ability to facilitate scale-up from laboratory processes to industrial-scale manufacturing. Initial experiments are typically conducted in small lab-scale bioreactors to optimize growth conditions. Once the optimal parameters are established, the process can be transferred to larger-scale fermenters, ensuring consistency and efficiency in production.

The biopharmaceutical sector particularly benefits from microbial cultivation, as it enables the production of complex molecules, including therapeutic proteins and monoclonal antibodies. Recombinant DNA technology allows scientists to engineer microorganisms to express desired proteins, which can then be harvested and purified for therapeutic use.

Furthermore, the fermentation process itself can add additional value to pharmaceutical products. Some microorganisms produce secondary metabolites during fermentation, which can enhance the efficacy of the primary product or provide additional therapeutic benefits.

By providing controlled environments that optimize microbial growth and product formation, bioreactors facilitate the efficient production of essential medications and biopharmaceuticals, ultimately contributing to advancements in healthcare and improving patient outcomes worldwide.